Evaluation of physical properties of polymers and nanomaterial composite polymers

Evaluation of physical properties of polymers and nanomaterial composite polymers

The word “polymer” can be used to describe a wide variety of polymers, from natural polymers such as cellulose and starch to synthetic polymers such as polypropylene and polyethylene terephthalate. When polymers are used as materials, they are often chemically or physically treated to extend their applications and functionality. In this laboratory, we evaluate the physical properties of polymers for and after such treatment.

The word “polymer” can be used to describe a wide variety of polymers, from natural polymers such as cellulose and starch to synthetic polymers such as polypropylene and polyethylene terephthalate. When polymers are used as materials, they are often chemically or physically treated to extend their applications and functionality. In this laboratory, we evaluate the physical properties of polymers for and after such treatment.

1.Viscoelasticity measurement of nanomaterial composite plastics and its application to evaluation of dispersibility

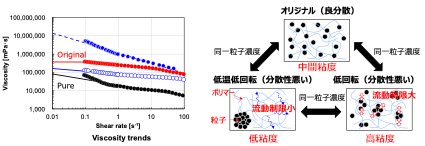

There are attempts to improve the properties of nanomaterials such as strength and heat resistance by compositing them with polymers to expand their applications. In this case, i) a method to homogeneously disperse the nanomaterials into the polymer is essential, and ii) it is important to evaluate the dispersibility. In this laboratory, we collaborate with other research institutes and other laboratories in Tohoku University to knead nanomaterials into polymers and to evaluate the dispersion of nanomaterials based on viscosity measurements.

1.Viscoelasticity measurement of nanomaterial composite plastics and its application to evaluation of dispersibility

There are attempts to improve the properties of nanomaterials such as strength and heat resistance by compositing them with polymers to expand their applications. In this case, i) a method to homogeneously disperse the nanomaterials into the polymer is essential, and ii) it is important to evaluate the dispersibility. In this laboratory, we collaborate with other research institutes and other laboratories in Tohoku University to knead nanomaterials into polymers and to evaluate the dispersion of nanomaterials based on viscosity measurements.

2.Evaluation of dispersion of cellulose nanofibers in polymers

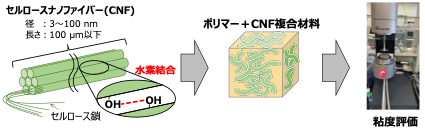

Cellulose nanofibers (CNFs), one of the natural polymer materials that can be produced from plant biomass, have been attracting attention in recent years because of their lightness while having a very strong structure. CNFs are expected to be one of the most promising reinforcing materials for polymers because they can be added to polymers to enhance their thermal and mechanical stability. In this laboratory, we fractionate CNFs with different properties by appropriate methods and evaluate the properties of polymer composites obtained by dispersing them.

2.Evaluation of dispersion of cellulose nanofibers in polymers

Cellulose nanofibers (CNFs), one of the natural polymer materials that can be produced from plant biomass, have been attracting attention in recent years because of their lightness while having a very strong structure. CNFs are expected to be one of the most promising reinforcing materials for polymers because they can be added to polymers to enhance their thermal and mechanical stability. In this laboratory, we fractionate CNFs with different properties by appropriate methods and evaluate the properties of polymer composites obtained by dispersing them.

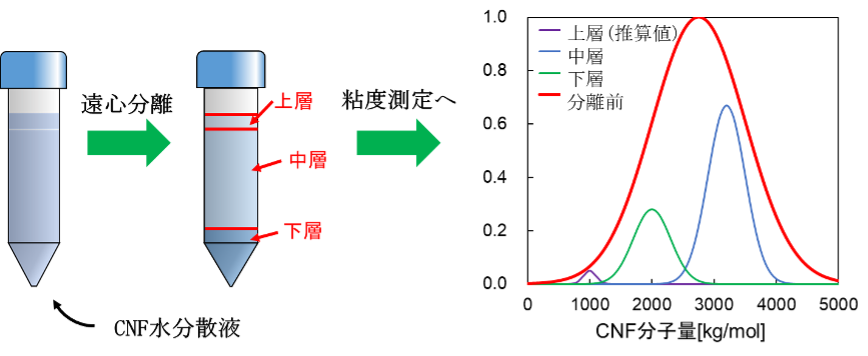

In order to promote the industrial use of CNF, we are also trying to predict the molecular weight distribution of mechanically disintegrated CNF, which has a wide range of molecular weight distribution. Specifically, we are attempting to predict the molecular weight distribution of CNF by fractionating CNF aqueous dispersions by centrifugation and measuring the viscosity of each fraction.