Material Control Process Engineering

Developing process design and optimization techniques based on precision mathematical modeling

Our lives are filled with various materials -- metals, semiconductors, polymers, ceramics and so forth -- which play a vital role in cutting-edge fields such as environmental systems, energy generation, medical science and biotechnology, as well as information, communications and electronics.

The laboratory is where new materials and production processes are designed and discovered. But in order to benefit from these discoveries, we need to be able to manufacture the new materials at the industrial level, in other words, with a higher speed and scale of production equipment and processes. In many cases, the end result is quite different to the laboratory experiments. This is because of variations in flow, temperature and concentration distribution within the equipment, which generate far more complex and nonlinear phenomena than those initially observed in the laboratory. The objective in industrial terms is efficient production of materials to the desired quality standard. To this end, we need to identify the causes of variation within equipment and processes, clarify the underlying mechanisms, and develop the appropriate controlling technology.

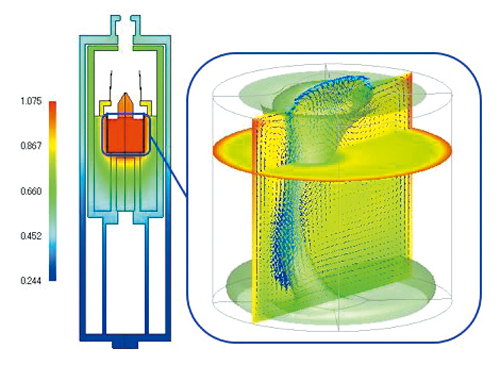

ctual industrial processes generally take place at very high temperatures and often involve highly reactive substances. Such conditions are not conducive to observation and measurement. Computer simulation can be used instead to explore the phenomena occurring within equipment and processes. At the Tsukada Laboratory, our work involves developing equipment design and process control techniques, mainly for material production processes, based on analysis of internal flow and macro-field temperature distribution in equipment using microscope observation and other optical techniques along with computer-controlled numerical simulation. More recently, we have been exploring the nature of macro field design and control techniques for regulating nano and meso scale material structures, based on the close correlation between the structural formation of materials at the meso level material and their resulting functions and qualities. To this end, we are developing models for nano and meso scale structural formation in macro fields.

Numerical simulation of transport phenomena in oxide monocrystal growth in the furnace environment

Main Research Themes

- Transport phenomena in semiconductor and oxide monocrystal growth process

- Transport phenomena in molten metal and semiconductor materials inside the electromagnetic levitation furnace

- Multi-component phase separation in non-uniform fields

- Dynamics of particle aggregation in liquid phase

- Transport phenomena in the functional polymer thin film production process

Professor of Chemical Engineering at the Graduate School of Engineering

Doctor of Engineering

Takao Tsukada

Graduated from Matsumoto Fukashi High School (Nagano Prefecture) in 1975. Completed a doctorate at the Tohoku University Graduate School of Engineering in 1984. Served as assistant professor at the Tohoku University Institute of Multidisciplinary Research for Advanced Materials and professor at the Osaka Prefecture University Graduate School of Engineering before assuming current position in 2008. "I loved mathematics in my junior and senior high school days. Somehow that turned into a career in chemistry, but I have made mathematics the central aspect of my work." The three keywords of the Tsukada Laboratory are: "Be absorbed," "Earnestly, boldly," and "Stay cool."